Как изготавливают натуральную жевательную резинку?

2023-10-20

How isNaturalChewingGumMade?

Chewing gum has been a favorite pastime for people of all ages for many years. However, not all chewing gums are created equal. While some contain natural ingredients, most of them are made of synthetic materials that can have negative impacts on one’s health and the environment. As a result, many manufacturers have been shifting towards producing natural chewing gum. If you're interested in learning how to make natural chewing gum in a factory setting, you're in the right place. In this blog post, we'll walk you through the process of making natural chewing gum.

Ⅰ.Preparation ofRawMaterials

The following raw materials are needed to make natural chewing gum:

1. Sugar: sugar, glucose, etc., as the main sweetener, to provide the sweetness of chewing gum.

2. Colloidal materials: natural plant colloids, such as gum arabic, yarrow gum, etc., used to form the colloidal base of chewing gum.

3. Additives: Vegetable oils, spices, colors, etc., used to adjust the taste and appearance of the chewing gum.

4. Molds: used to press the shape of chewing gum, you can choose different shapes and specifications of the mold.

Ⅱ.ColloidBaseMaterialPreparation

The preparation of colloidal base material is an important step in the production of natural chewing gum. Specific steps are as follows:

1. Mix the sugar and colloidal material according to a certain proportion.

2. Heat the mixture to a certain temperature, so that the colloidal material is fully dissolved.

3. Stir the mixture continuously to avoid burning or solidifying.

4. After the mixture cools down, put it into the refrigerator for a period of time to make the colloidal base more stable.

Ⅲ.Ingredients andMixing

Blending the ratio of ingredients for the best taste is a key step in making natural chewing gum, the specific steps are as follows:

1. Mix the prepared sugar, colloidal base and other additives according to a certain ratio.

2. Stir the mixture to make it well homogenized.

3. As required, appropriate amount of water or other conditioners can be added to improve the taste or performance.

4. Continuously stir the mixture until it is uniform and fine.

Ⅳ.HeatingPaste

The colloidal base material and ingredients for heating paste, is to ensure the success of the production of natural chewing gum is an important link, the specific steps are as follows:

1. Heat the mixture to a certain temperature, so that it is fully pasted.

2. Stir the heated mixture continuously to avoid burning or solidifying.

3. When the mixture becomes transparent and homogeneous, it means that it has reached a suitable paste state.

4. After pasting, cool the mixture slightly for subsequent operations.

Ⅴ.AddWax

The addition of waxes serves to soften the chewing texture of the gum at all stages of chewing and reduces the melting point of the gum base during processing. The steps are as follows.

1. Choose suitable waxes, such as beeswax, paraffin, etc., and adjust its melting point according to the demand.

2. Cut the waxes into small pieces for easy dissolution.

3. Dissolve the waxes in vegetable oil to form a homogeneous solution.

4. Add the wax solution to the colloidal base material which has been cooled to a suitable temperature and mix well.

VI. Cooling

The heated mixture needs to be cooled quickly in order to solidify into chewing gum. Natural cooling is a common method, in which the mixture is poured into cooling pans and allowed to cool naturally in the air. In order to speed up the cooling process, factories usually place the gum in a freezer for cooling and shaping.

VII. Pressing

Put all the materials into the mold for pressing to form the shape of natural chewing gum as follows:

1. Prepare the mold and make sure it is clean, waterless and free of impurities.

2. Pour the heated natural chewing gum material into the mold.

3. Scrape the surface of the material with a flat tool to make the thickness even.

4. Cover the lid of the mold and press it through the press for a period of time until the chewing gum cools and solidifies.

VIII. Cutting

The finished natural chewing gum will be cut, so that its size and thickness and other parameters in line with the requirements, the specific steps are as follows:

1. Confirm that the chewing gum has been completely cooled and solidified to facilitate cutting.

2. Use the cutting machine to cut the chewing gum into the required size and shape.

4. Screening the cut chewing gum to remove the gum that does not meet the specifications.

IX. Packaging

Packaging natural chewing gum can protect the product and improve the standard of hygiene, the specific steps are as follows:

1. Select packaging materials according to the needs, such as plastic bottles, cartons, aluminum foil bags, etc..

2. Put the natural chewing gum into the bag, pay attention to avoid air entry, minimize the air inside the bag, and then seal it.

3. Check whether the package is intact, to avoid problems such as air leakage or rupture during the packaging process.

4.Place the packaged natural flavored candies in a clean cardboard box or plastic crate for transportation and storage.

5. Label the outside of the carton or plastic crate with the product name, production date, shelf life and other information to facilitate management and consumer understanding of the product.

FAQ

What is theDifferenceBetweenNaturalChewingGum andOrdinaryChewingGum in theProductionProcess?

Natural chewing gum and ordinary chewing gum in the production process is the main difference between raw materials and production process.

1. Raw materials: natural chewing gum raw materials mainly include natural gum or artificial synthetic gum, sugar, honey or sugar alcohol, spices and coloring. The main raw materials of ordinary chewing gum in addition to gum, sugar, may also include some synthetic coloring, synthetic flavors and other ingredients.

2. Production process: natural chewing gum production process mainly includes ingredients, mixing, heating paste, waxing, pressing and packaging steps. While the production process of ordinary chewing gum may include ingredients, heating and melting, foaming, molding, cooling and curing and other steps In addition, ordinary chewing gum in the production process, in order to make it have a longer shelf life, may add some preservatives and other ingredients. Natural chewing gum, on the other hand, generally does not need to add these ingredients, so its shelf life may be shorter.

InThe Processof Making Natural Chewing Gum,howto EnsureThe Qualityand StabilityofThe Product?

In the process of making natural chewing gum, to ensure the quality and stability of the product, you need to pay attention to the following aspects:.

1. Raw material selection and procurement

Raw material quality: Choose suppliers with good reputation to ensure that the quality of raw materials meets the standard requirements. For example, the gelling agent should have proper consistency and good elasticity; powdered sugar should be dry and free of lumps; flavors should be high purity and free of peculiar smell; pigments should have natural color and no bad taste.

Stability of raw materials: choose raw materials with good stability to ensure product shelf life and taste stability. For example, some raw materials may require specific storage conditions (such as temperature, humidity, etc.) in order to maintain their properties.

2. Raw material storage and custody

Temperature control: The storage temperature should be in line with the storage requirements of raw materials, too high or too low temperature may lead to deterioration of raw materials. For example, gelling agent at high temperatures may become soft and lose elasticity, while low temperatures may lead to moisture condensation.

Humidity control: For raw materials susceptible to humidity, such as certain spice plants and natural sweeteners, the humidity of the storage environment should be kept as stable as possible to avoid raw materials affected by moisture and affect product quality.

Isolated storage: Different types of raw materials should be stored separately to avoid the mutual influence of different raw materials. At the same time, should avoid coexistence with toxic substances or odor substances to avoid contamination of raw materials.

3. Quality control in the production process

Standardized production: Develop and implement strict production processes and operating procedures to ensure that each batch of products are made in accordance with standards.

Quality Inspection: Conduct necessary quality inspection on semi-finished and finished products during the production process, including testing of ingredients, microbial indicators, heavy metals, etc., to ensure that the products comply with relevant standards and regulations.

Conclusion:

Making natural chewing gum requires a lot of care, attention to detail, and quality materials. It's a growing industry that’s only set to get bigger thanks to people's increasing concerns about the health and environmental impacts of synthetic chewing gums. The process of making natural chewing gum is complex, but it’s also rewarding as it gives consumers the satisfaction of knowing that they're chewing gum made with natural ingredients and a lot of love. Next time you chew a piece of natural gum, take a minute to appreciate the effort and dedication that goes into making it.

Суйфа Новости

Получите мгновенное предложение

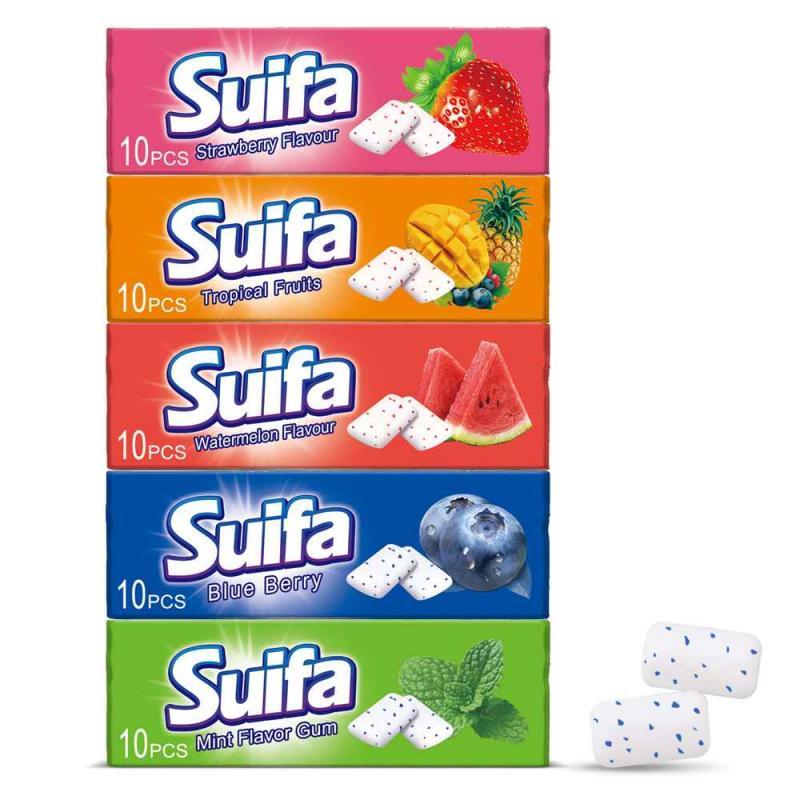

Рекомендуемые продукты

Жевательная резинка без сахара с ксилитом, натуральная и полезная в больших упаковках.

Деталь

Энергетическая жевательная резинка с женьшенем без сахара

Деталь

Проверка заказа

Качественный тест перед доставкой

Проверьте детали при упаковке

Упаковка и транспорт

Отправить запрос сейчас!

Выберите Suifa, Повысьте свой проект Candy и Gum!

Откройте для себя отличные жевательные резинки и конфеты на нашем заводе. Мы создаем индивидуальные решения для наших клиентов. Присоединяйтесь к нам для эксклюзивных идей, индивидуальных продуктов и партнерских отношений. Оставьте свою Контакты информацию, мы свяжемся с вами в течение 12 часов!

Выберите Suifa, возьмите свой бизнес на новый уровень!

Контакты Нас

ДОБРО ПОЖАЛОВАТЬ НА SUIFAFOOD ВАШ ДОВЕРЕННЫЙ ПРОИЗВОДИТЕЛЬ ГУМА И КОНТЕНДИ

Адрес: No.8 Ritian Road Songxia промышленная площадь Songgang Nanhai, Фошань, Гуандун, Китай

Электронная почта: henry@suifafood.com

Электронная почта: henry@suifafood.com